Article published on “Perforare”, January 2016.

DAT instruments’ best seller, the JET 4000 AME / J datalogger, can be set as a project.

Many people may consider electronics as an enemy of construction worksites. On the contrary, electronic technology, if used properly, is a precious partner that simplifies work, even the hard work associated with drilling jobs. In this specific context, DAT instruments’ dataloggers are electronic devices designed and made specifically to simplify life on site, to make operator’s task easier, and to carry out jobs according to the client’s specific needs. Taking this philosophy as a basis, this company from Lombardy has created all its products so that they can be used for machines of any make and size, and used for the widest ranging applications and technologies in underground works. Among the latest innovations introduced by DAT Instruments, there’s an option to setting the JET 4000 AME / J datalogger (one of DAT instruments most appreciated products) as a project. The system is very simple.

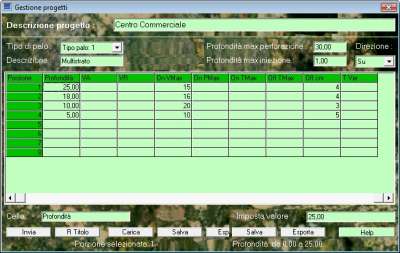

Many people may consider electronics as an enemy of construction worksites. On the contrary, electronic technology, if used properly, is a precious partner that simplifies work, even the hard work associated with drilling jobs. In this specific context, DAT instruments’ dataloggers are electronic devices designed and made specifically to simplify life on site, to make operator’s task easier, and to carry out jobs according to the client’s specific needs. Taking this philosophy as a basis, this company from Lombardy has created all its products so that they can be used for machines of any make and size, and used for the widest ranging applications and technologies in underground works. Among the latest innovations introduced by DAT Instruments, there’s an option to setting the JET 4000 AME / J datalogger (one of DAT instruments most appreciated products) as a project. The system is very simple. Thanks to the JET S 104 software – also designed and made by the Italian company’s technical department – the client is able to use the “project” function; that’s to say, all the various steps for completing the jet grouting column can be set, at various depths. Usually, with this kind of technology, each upward step is done according to many parameters; the pause can be based on the litres of concrete to be injected, the concrete pressure, or a time basis. Thanks to DAT instruments’ system, the step movement can be set according to a simple time as well or, much more exactly, in relation toa specific height, expressed in centimetres. Everything is calculated and entered in the worksite’s project specifications. At a practical level, the client needs do nothing more than enter this data in a specific JET S 104 software sheet and, by using the JET C USB data transfer system, send the project data to the datalogger. At this stage, everything becomes much simpler for the operator. Whoever is operating the drilling machine, just have to select on the datalogger the “pile type”, the same already entered on the PC, and everything is then up to the onboard datalogger that sets the various rod movements according to the specific project, avoiding any errors. Using the JET 4000 AME / J datalogger in “project” mode is a particularly effective system when dealing with a complex stratigraphy. It was recently used on a worksite in Singapore, where the various steps had to be set according to the various ground strata and, as a consequence, had different parameters. To deal with this problems, the technician in the office simply set the project data in the PC software, depending on the different depths, and then sent everything to the datalogger. This meant that the operator did not have to worry about anything: the datalogger modified all the relevant parameters automatically for the various depth steps.

Thanks to the JET S 104 software – also designed and made by the Italian company’s technical department – the client is able to use the “project” function; that’s to say, all the various steps for completing the jet grouting column can be set, at various depths. Usually, with this kind of technology, each upward step is done according to many parameters; the pause can be based on the litres of concrete to be injected, the concrete pressure, or a time basis. Thanks to DAT instruments’ system, the step movement can be set according to a simple time as well or, much more exactly, in relation toa specific height, expressed in centimetres. Everything is calculated and entered in the worksite’s project specifications. At a practical level, the client needs do nothing more than enter this data in a specific JET S 104 software sheet and, by using the JET C USB data transfer system, send the project data to the datalogger. At this stage, everything becomes much simpler for the operator. Whoever is operating the drilling machine, just have to select on the datalogger the “pile type”, the same already entered on the PC, and everything is then up to the onboard datalogger that sets the various rod movements according to the specific project, avoiding any errors. Using the JET 4000 AME / J datalogger in “project” mode is a particularly effective system when dealing with a complex stratigraphy. It was recently used on a worksite in Singapore, where the various steps had to be set according to the various ground strata and, as a consequence, had different parameters. To deal with this problems, the technician in the office simply set the project data in the PC software, depending on the different depths, and then sent everything to the datalogger. This meant that the operator did not have to worry about anything: the datalogger modified all the relevant parameters automatically for the various depth steps.

The other functions

In addition to the “project” function, the datalogger can regulate the rod rotation speed and the continuous rising speed using the optional rotation speed and proportional rising control board. For those who are mad about precision, the datalogger can also be set to read the depth in millimetres, making the measurement and automation even more precise. The “project” function and all DAT Instruments products will be available to operators at the next Bauma in Munich (stand 250, pavilion C2).