How Your dataloggers are made

Design, manufacture and tests of our dataloggers are carried out in our labs.

Design, manufacture and tests of our dataloggers are carried out in our labs.

STEP 1: agreement with our customer

Our customer agrees with DAT instruments the characteristics he needs in its plant.

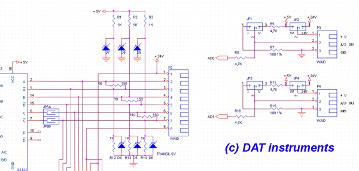

STEP 2: design

The instrument is customized by our design dpt according to previously agreed customer indications.

STEP 3: warehouse

All components necessary to make our instruments are taken from our warehouse which is well provided. In order to manufacture our products more than 1500 different components are necessary, each one bought from top quality suppliers!

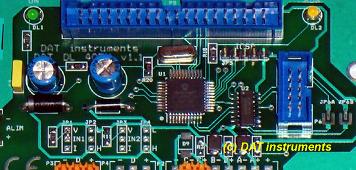

STEP 4: electronic assembly

In order to ensure the necessary expertise, assembly of electronic boards is carried out in our labs.

This is the real “made in Italy” !

STEP 5: electronic test

Each electronic board produced by our technicians is individually programmed and tested. Nothing is due to chance.

STEP 6: instrument assembly

All electronic boards, LCD, keyboards, cables and cases are assembled to make the electronic instrument.

STEP 7: instrument test

The whole instrument is tested and adjusted in different phases even if each single component is tested individually. Tests last many hours and they check every possible error cause.

STEP 8: order completion

Sensors, mechanical parts and connection cables are added to the tested electronic instrument. Even sensors and connection cables are tested before being delivered to the customer.

STEP 9: installation

This instrument is installed on customer plant everywhere it may be. During installation, operators are involved, in this way the necessary training is carried out.