DAT instruments – specialized in the production of data logging instrumentation designed for geotechnical and special foundations activities – has designed and launched a product aimed to work in tunnelling projects.

DAT instruments combines accurate electronic equipment with long performance sensors to face pre-drilling activities, with the purpose of investigating the ground to be dug and the vault of a tunnel when a TBM is in operation.

Underground works, especially tunnelling works must consider all soil strata. Continuous monitoring of the geological pattern is required to acquire quickly soil information and deliver the best result on time, not only during the excavation of the TBM but also during the process of soil investigation, above the tunnel vault.

Underground works, especially tunnelling works must consider all soil strata. Continuous monitoring of the geological pattern is required to acquire quickly soil information and deliver the best result on time, not only during the excavation of the TBM but also during the process of soil investigation, above the tunnel vault.

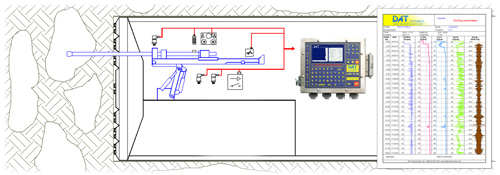

Here is where DAT instruments, specialist within the production of drilling and piling electronic monitoring instrumentation, had the opportunity to install a datalogger on a small drill rig, placed on the TBM. The purpose was to pre-drill the soil before the TBM excavation, allowing a faster and longer daily dig.

There are two major benefits by using the instrumentation of DAT instruments: monitoring soil structure even 70m at the front of the TBM and investigation of soil above the tunnel vault.

Thanks to the small driller on which it is installed, the datalogger allows to test and explore the land in front of the TBM, recording the diagraphy before the dig of the tunnel. In this way the building company perfectly knows the characteristics of land that it is going to dig and the best equipment to be used, avoiding a premature usury of the cutting parts and increasing the productivity.

At the same time the TBM auxiliary drilling machine can be used to test the vault of the tunnel (that operation usually does not reach 5 m of depth) aimed to define the type of soil to be faced, to choose the best coating to be taken and to determine the final type of sensors that will monitor the tunnel during the entire life of the structure. Last but not least: the data logger provides an opportunity to certify the work, allowing you to deliver to the project manager a detailed description of each dig.

At the same time the TBM auxiliary drilling machine can be used to test the vault of the tunnel (that operation usually does not reach 5 m of depth) aimed to define the type of soil to be faced, to choose the best coating to be taken and to determine the final type of sensors that will monitor the tunnel during the entire life of the structure. Last but not least: the data logger provides an opportunity to certify the work, allowing you to deliver to the project manager a detailed description of each dig.

From a technical perspective the datalogger created by DAT instruments for this particular type of processing is the JET 4000 AME / J, equipped with a special set of sensors that allows data transfer through USB pen drive and to process the parameters using the software JET S 104. There are several parameters recorded by the DAT instruments equipment, including: drill depth, rod feed force, rod feed speed, rotation torque and rotation speed; mast inclination axes X and Y (optional); drilling fluid pressure, date and start/end time of work and duration of work, calculation of relative energy of the ground.

Assistance and worldwide support

Although the dataloggers and sensors are highly sophisticated electronic instruments, they are not delicate. All products DAT instruments are made keeping in mind the work site where they will operate, with a large use of stainless steel and polymer resins of latest generation that ensure maximum strength and durability. However, the Italian company has developed a service that leaves no room for doubts and uncertainty and has as main objective the proximity to the customer and his site problems.

As stated by Amedeo Valoroso, owner of DAT instruments: “we have local distributors all over the world with high-level technical assistance, capable of carrying out any installation and support customers during the use of the instrumentation. Reseller technicians are formed directly by us and continually supported by Italian experts, always ready to intervene in the work site for any need or be able to dispel the customer doubts through modern systems always more appreciated.

In fact DAT instruments has always been available to solve problems by phone, e-mail or Skype. However today our service has evolved, with the opportunity to realize video conferencing with operators in the pipeline. It is possible to install and configure the software remotely, in order to make life easier in the work sites. It is also possible to make education and training. “

A successful example: the BBT

A successful example: the BBT

Among the many successful applications recorded by DAT instruments in the specific field of tunnelling, the intervention in the Brenner Base Tunnel or Brenner Base Tunnel (BBT), appears one of the most significant because of the importance of the work at European level but also for the specific commitment of the Italian company that with his staff has followed all the stages of the building, installation assistance.

The Italian technicians have been involved in the pre-drilling of the service tunnel built transversely to the main rail tunnel linking Italy to Austria. A gallery of 10 kilometers with a width of about 6-7 m. In this site the data logger was installed on a small drill that had the task of testing the waters to about 70 m, anticipating the work of the TBM of 20-25 m

At the same time the drill, rotating 90 °, has done surveys of the entire of the tunnel providing precise diagraphies of the ground ahead of the TBM.