The works for the Rochor Canal enlargement, in Singapore, have been performed with the use of datalogging systems, provided by the Italian-based company DAT instruments, which have been installed on the machines of the subcontractor in order to control and certify the jet grouting operations.

Italian technology is all about high quality worldwide. One of the most recent applications is the electronic instrumentation (both hardware and software) developed by DAT instruments and installed on some drilling rigs now working in the heart of Singapore.

THE SITE

The floods which occurred in Singapore in June and July 2010 and caused damages for more than 23 million dollar, made the local authorities design the enlargement and drainage of the Rochor Canal, one of the biggest canals going through the city-state.

The project, started some months ago, will involve also the areas called Bukit Timah, River Valley and Geyland and joins into a large national plan aimed at the dramatic reduction of the floods taking periodically place in the city.

The P.U.B. agency, coordinating the works, has developed a project of traffic diversion aimed at minimizing the impact of the works on the city dwellers, also considering that in the Rochor Canal area the works for the Downtown MRT Line are already taking place.

Both the projects – the canal enlargement and the underground – will involve also the L.T.A. (Land Transport Authority), which will play an important role in preventing the operations from affecting too much the life and economic activities of the area.

Actually, according to the local newspaper “The Straits Times”, the greatest supporters of this project are the shopkeepers and citizens living in this area: this is the only viable way to reduce the risk of floods, which are often bearers of huge economic damages, without considering the concrete risk for the residents’ safety.

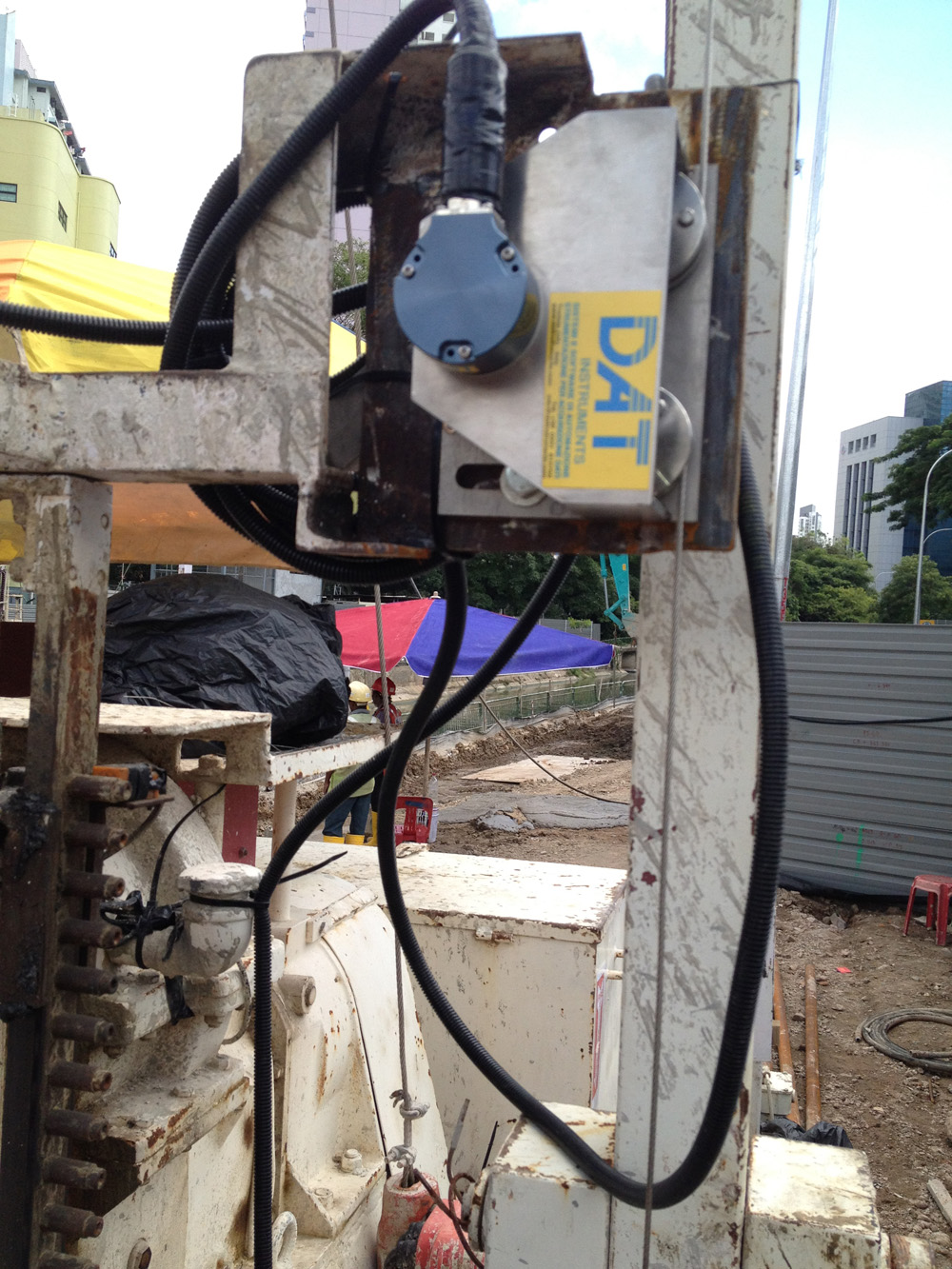

For the quay and foundations reinforcement the designers opted for the jet-grouting technique, controlled by two JET 4000 AME/J dataloggers by DAT instruments.

CONTROLLING AND CERTIFYING THE JET-GROUTING

At the moment there are two machines equipped with the Italian dataloggers but in the next weeks the number is going to double, given the high benefits brought by this instrumentation.

“To sum up – underlines a technicians of the company – the JET 4000 AME/J dataloggers installed on our drilling rigs ensure the total respect of the jet-grouting parameters, in compliance with the precise technical instructions approved and deliberated by the Public Utilities Board (P.U.B.) and the management of operations in charge, Surbana Consultants. The graphs obtained represent the proof which certifies the work done and can be referred to at any time in case of technical problems”.

In practice, this control system verifies and guarantees a regular flow of information for the client about each project step, showing that all the piles have been made in compliance with the specifications dictated.

But which are the real benefits brought by a DAT instruments datalogger to the jet-grouting work?

The use of a JET 4000 AME/J involves the direct display on the datalogger LCD of instantaneous and average values, graphics in function of depth and summarizing data. Moreover, the instrument enables the automatic start of the equipment when starts recording, the automatic stop when reaching required depth and the automatic management of step time of rod ascent. All data are automatically downloaded to the computer of the company, which is then able to process, file, export and print them. More in particular, the JET 4000 AME/J, thanks to its sensors, measures and records – both during drilling and withdrawal rod movement – several parameters, such as: drill depth, feed force, translation rod speed, boring rod rotation torque and speed, X and Y mast inclination, cement pressure and flow, water pressure and flow, air pressure, rod rise step time, injected column length, date and time of drilling/jetting and duration and finally soil relative energy.

All recorded data are stored on three large internal memories and then can be transferred to a PC which has JET S 104 software installed via a simple USB pendrive, JET RACK USB or JET C USB cable. The software, produced internally in DAT instruments as well, let you organize and elaborate data, draw graphics and tables and print them very easily. Moreover, it is also available a function to export data to Microsoft Excel. It is important to underline that the datalogger of the Italian manufacturer can work also in case of hazardous conditions: from -10 up to +60°C.

THE INTERNATIONAL MARKET

The Singapore site is not an exception for DAT instruments. The export turnover, for the company based in Cairate (Italy), is becoming more and more important, in particular in this period of persisting crisis and is giving excellent results. “We decided to enter the international market in 2008 – confirms Amedeo Valoroso, founder and owner of DAT instruments – and it has been a hard challenge for us: we had to hire sales manager for the foreign markets, translate the products and the software, take part in many international exhibitions. Anyway we obtained good results in very few years, also with the support of several resellers worldwide. In particular, in the Asian market we are present in Singapore, Hong Kong, Taiwan, Thailand, Indonesia, China and India.

ENHANCE “MADE IN ITALY”!

The opening towards the international markets should not hide the truth situation: DAT instruments is an Italian company designing and producing high-tech instruments using components coming from the European market.

“ I believe – says Mr. Amedeo Valoroso – the high quality Italian product can have something more than the foreign competitors’ ones. The internal production means, for us, a deep knowledge of the product and a high customization ensured for each client. Italian quality means spending the right money in terms of materials, which must always be at the top. Moreover Italian availability means being always present in case of any need: for modifications, assistance or simply for some advice. In these years I could notice how foreign clients appreciate Italian quality. The important is to demonstrate the value of the product and our presence at any time. Having international ambitions does not mean to pervert the nature of the company but continuing improvement of the product and of the assistance. For this purpose each product is tested by several people in the most diverse weather conditions and on different machines. All these trials and tests help us improving all the range of dataloggers, with evident benefits for the drilling companies, both foreign and national, which use our instruments. In connection with this I want to underline our wish for the future to be closer and closer to the field workers: indeed we are developing for our products and software several new functions, all designed according to direct agreements and requests with the personnel in many fields in Italy and worldwide”.