Possible situations:

Possible situations:

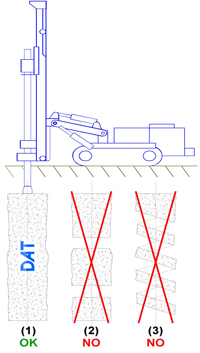

(1) The first pile was properly built using JET 4000 AME / J: The rotation speed and rod rise were set up correctly and the pump was able to provide the required cement flow and pressure.

(2) This pile was badly built, compromising its bearing capacity: the pump may have stopped at some sections but the rod kept rising, hence not providing cement. JET 4000 AME / J would have suspended the pile lift, avoiding gaps within the pile.

(3) This pile was badly built, compromising its bearing capacity. The rod rise speed and rotation speed set ups did not follow the project specifications.

Solution by DAT INSTRUMENTS:

- Controls the rig during the pile injection, by automating rod rotation and rod rise speeds in relation to the project parameters;

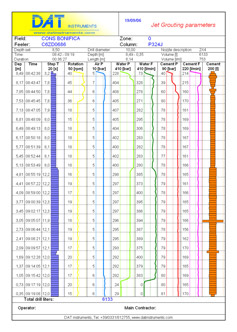

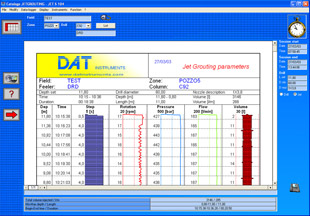

- Measures parameters such as depth, rod rotation and rise speed; rotation torque and feed force; pressure, flow and volume of cement; step time, if needed; date, time and duration;

- Provides detailed reports to document the work quality; reports are easy to access and to manage;

- Provides soil relative energy (while drilling) for each pile that has been built;

- Can be set up with all the project specifications of the piles to be made.

NO NEED TO SET UP IN FIELD.